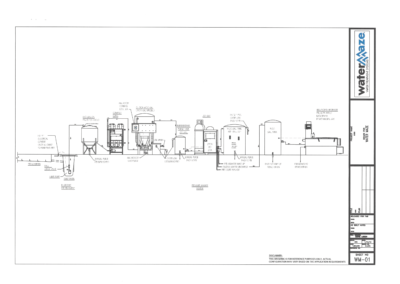

Indianapolis Water Maze® Water Reclamation & Wastewater Treatment Systems

Since the late 1980s, Water Maze has been perfecting the art and science of water reclamation & treatment to provide Indianapolis wash water reclamation & treatment systems. Our Indianapolis washwater treatment system professionals have incorporated various technologies that are capable of: settling heavy solids, removing suspended solids; skimming free-floating oils; removing emulsified oils; bio-remediating organic matter; and reducing (evaporating) water. Our washwater reclamation & treatment system experts provide systems for discharge to the Indianapolis sewer, as well as for recycling water for a limited time period.

Above-ground Cone-bottom Tanks

Water Maze CLT-600 and CLT-300 models can be applied as pre-treatment, post treatment, or as a stand alone treatment system. These models utilize cross-linked polyethylene cone-bottom tanks with steep slopes (up to 55 degrees) for maximum solids separation. Each tank has a full open top with removable lid and includes heavy duty metal stand with cradle. These base models are also incorporated into other clarifier models within this products catalog with features and benefits to match your application requirements.

Universal Clarifier System

Customized clarifiers can incorporate many options tailored to your unique situation. Start with a bare tank and add the options to optimize the treatment of your water. The CLT models are capable of pre-treatment, sewer discharge or recycling of wash water with flow rates of up to 30 gallons per minute. Not limited to but may include, belt-mop skimmer, auto-purge systems, auto-circulation systems, pH (only) controller, ORP/pH controller, dual pH Controller, and Bioremediation.

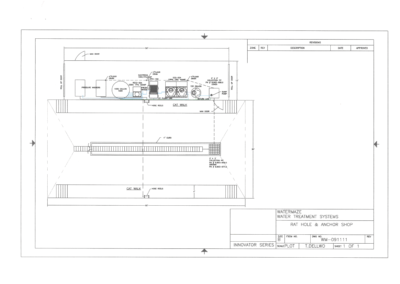

REC-ZCF3-30A

The REC-ZCF3-30A is a major advance in filtration performance. Delivering superior recycled water quality with fully automatic operation, the plug-and-play unit is pre-piped and wired, ready for connection to tanks and wash process. Flexible programming and self-cleaning backwash cycles enables large volumes of waste water to recycle while generating a minimum amount of waste volume. Using robust, industry-standard components built into a highly functional structural steel frame with a stainless steel base. As a powerful and flexible pumping and filtration system that can serve as the hub of a wide range of Indiana wash water treatment system processes.

Water Blaster

25 GPM and 500 PSI. 2 Electrical Configurations. Rugged self-priming, high-pressure diaphragm pump

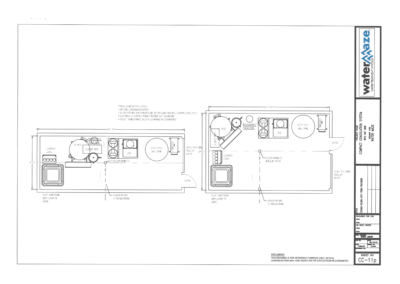

Compact CoAg Water Management Center

The Compact CoAg employs chemical coagulation and flocculation water treatment technology to enhance and speed up the process of removing suspended solids and most types of emulsified oils. This product utilizes a patented process for applying and mixing proprietary blends of chemical coagulant (CoAg+) and flocculant (EC+) to effectively de-emulsify oils and to agglomerate suspended solids.

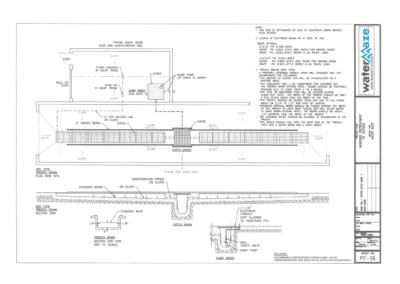

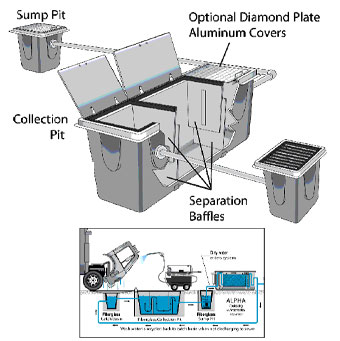

Inground Fiberglass Pit

Reinforced, pre-fabricated fiberglass pits are significantly easier and less expensive to ship and install than shipping or constructing on site pits made of concrete. The fiberglass is chemically resistant and the inner surfaces are impervious, which inhibits the growth of bacteria. When they are properly installed (e.g., immersed in concrete), they effectively can provide double containment in case of ground movement.

WB-50A Wastewater Evaporator

The WB-50A Water Blaze is a submerged combustion water evaporator. This super energy-efficient wastewater evaporator system with patented design uses submerged combustion technology whereby heat is forced through a submerged tube and released directly into the water for 100% heat exchanger efficiency and dramatic operational and energy cost savings.

HBG-30D Wastewater Evaporator

The HBG-30D is a natural gas or propane heated water reduction tool capable of evaporating wastewater up to 30 gallons per hour. It contains a combustion box made of advanced heat resistant material and features a unique energy-efficient design for reflecting the heat directly onto the floor of the evaporation tank for energy cost savings. An electric system with multiple industrial grade, electric, coiled burners is mounted under the evaporator tank in easy-access service tray.

Water Maze PM-1000D

The PM-1000D provides a fully automated, environmentally friendly and low-cost way to manage standing wash water found in collection pits, tanks or sump drains. It is designed to be integrated into most wash-water treatment systems utilizing aeration and automatic injection of a highly effective microbial agent for eliminating oils, greases and other hydrocarbons and organics typically found in collection pits or sump drains.